Wyoming State Water Plan

Wyoming State Water Plan

Wyoming Water Development Office

6920 Yellowtail Rd

Cheyenne, WY 82002

Phone: 307-777-7626

Wyoming Water Development Office

6920 Yellowtail Rd

Cheyenne, WY 82002

Phone: 307-777-7626

| SUBJECT: |

Appendix Q Industrial Water Needs Projections |

| PREPARED BY: | Watts and Associates, Inc. |

| DATE: | March 2002 |

INTRODUCTION

This memorandum presents projections of industrial water needs in Northeast Wyoming River Basins for the period from 2000 through 2030. These projections provide a basis for gaging the adequacy of existing water resources in the Basin to meet potential future needs. Following guidelines established by the Wyoming Water Development Commission (WWDC), projections were developed for three planning scenarios:

APPROACH

The projections described in this memorandum are based upon a review of available literature and a series of personal interviews with planning and regulatory officials and representatives of large industrial water users in the Basin. A database of industrial water rights permit holders provided by the State Engineers Office (2001) was used to develop an initial list of large industrial water users in the planning area. This initial list was refined as the interviews proceeded to insure that potential future users were identified and included in the study. A total of 24 interviews were completed with persons knowledgeable of water use in the following industries:

COAL-FIRED ELECTRIC POWER PRODUCTION

As of late 2001, four coal-fired electric power plants were operating in the planning area.1 Three of the plants, Neal Simpson #1, Neal Simpson #2, and Wyodak #1, are located near the Wyodak coalmine seven miles east of Gillette. They use coal from the Wyodak Mine and have a combined generating capacity of about 430 megawatts (MW). The largest of the plants, Wyodak, has a nameplate capacity of 330 MW and is owned by PacifiCorp. Black Hills Power and Light is the predominant owner of the smaller Neal Simpson units, which have a combined generating capacity of about 100 MW.

The interesting characteristic of all three of these plants is that they use air rather than water for cooling steam produced during electric power generation. As a result, their water consumption is significantly lower than is the case for more conventional water -cooled electric power plants. The three plants located at the Wyodak site use about 500 acre-feet of water annually, and most of this water is obtained via pipeline from the Gillette sewage treatment facility. This wastewater is further treated at the Wyodak site before being used for process water, primarily for steam production (Henshaw, 2001).

The only water-cooled electric generating facility in the planning area is the Osage Station, located near Osage in Westin County. This 33 MW facility went on line in 1948, and uses water from three Madison Formation wells for cooling purposes. Precise consumptive use estimates are not available, but the plant apparently uses about 400 acre-feet of water annually based upon company estimates (Roeper, 2001). Thus, total annual water use for power production in the planning area is approximately 900 acre-feet annually.

The Osage facility is permitted to operate only through the year 2010, which is the end of its design life. Black Hills Power and Light would have to re-permit the facility to continue operating after that date, and is unlikely to do for a variety of reasons, including the fact that coal burned at the plant must be trucked long distances from the Wyodak Mine. There seems little doubt, however, that additional coal-fired electric generating capacity will be constructed in northeast Wyoming to more than offset lost production from the Osage Plant. What is in doubt is the magnitude and timing of that expansion and the amount of water that will be required to support it.

Although the planning area has abundant coal resources to support additional electric power generation, additional capacity has not been added in recent years for several reasons. Among those reasons is the uncertainty imposed upon the electric power industry by proposals to deregulate it in various western states. Without assurances that they would be able recover costs in deregulated markets, electric power generators have been reluctant to make large capital investments in new facilities. Furthermore, transmission facilities out of the Basin to growing markets such as Colorado are nearing capacity and would have to be expanded to support significant amounts of new generation, thus adding to capital investment requirements (Parrish, 2000).

Events of the past two years, however, including power shortages in California, rapidly rising prices for electricity, and new federal incentives for plant construction, have shifted the economic climate with respect to developing new generating capacity. Several companies have announced plans to build additional generating capacity in the planning area, and those plans are in various stages of implementation. A summary of announced capacity expansion plans as of August 23, 2001 is given below.

If all of these facilities were built, generating capacity in the Basin would rise from 463MW today to 2,820MW at some point in the future.2 It is possible that some announced facilities will not be built, however, due to financial considerations or permitting difficulties that may arise in the future. On the other hand, plans for other facilities not yet announced may be forthcoming over the 30-year horizon of this planning study.

The plans for plants that have been announced involve dry cooling towers and limited usage of groundwater for process purposes. Water requirements for dry-cooled plants are much less than for plants with wet cooling towers, which are in use at other locations in the state, including the Laramie River Station in Platte County and the Jim Bridger Power Plant in Sweetwater County. While wet-cooled plants are more efficient and less costly to run than dry-cooled plants, their water requirements are much larger. For example, the 2000MW Jim Bridger Plant consumptively uses about 34,000 acre-feet of water annually (Watts, 2000). This figure is much larger on a per-megawatt basis than the estimated 500 acre- feet of annual consumptive use by the dry-cooled plants at the Wyodak site near Gillette.

The disadvantage of wet-cooled plants is that it can be very expensive to pump large quantities of groundwater or transport large quantities of surface water over long distances. Most wet-cooled power plants are located close to an adequate surface water source. At least one power producer in the planning area has evaluated the feasibility of constructing a pipeline from Lake DeSmet to a site near Gillette to provide water for wet cooling. The cost of the pipeline was so large that dry cooling proved to be a more feasible option for power production at that location (Henshaw, 2001). Given the fact that there is relatively little surface water available in proximity to the coal resources of the planning area, it appears likely that dry cooling will remain the technology of choice for power production for the foreseeable future.

One factor that might change that conclusion is the availability of low-cost groundwater from coalbed methane (CBM) production in the planning area. The process of extracting methane gas from coal seams produces large quantities of water that must be disposed of in some fashion, and use of that water for wet cooling in electric power production would be a logical way to make use of water that would otherwise be re-injected into aquifers, stored in small reservoirs, or discharged into streams. At least one power company has expressed an interest in utilizing CBM water for cooling purposes (Ruffato, 2001).

There are several potential problems with implementing such a proposal, however. One problem is the fact that although the production life of coalbed methane resources in the Basin is not known with certainty, resources may be depleted in a shorter time frame than the 50-plus year life expectancy of a coal-fired generating facility. Of even greater concern is the fact that water production from coal seams tend to peak when the seam is first tapped, and then drop off dramatically as methane production increases, meaning that there is a great variation in the amount of water produced at one location over time. Finally, the CBM industry is composed of a large number of players who have priorities other than insuring a reliable source of water for industrial use. Organizing those individuals and companies and providing the infrastructure needed to transport a consistent volume of water to a site for cooling purposes could prove to be a daunting challenge. Nevertheless, the potential use of CBM water for industrial purposes in the Basin remains an interesting possibility.

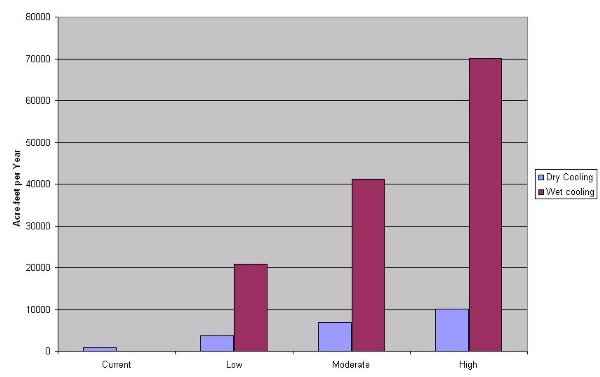

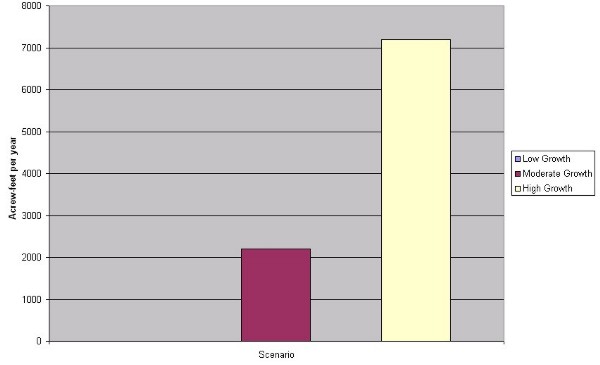

Projections of future water needs for electric power generation are described below for low, moderate, and high growth scenarios. These projections are based upon the assumption that dry cooling and limited groundwater pumping for process water will continue to be the predominant technology employed. For comparison purposes, however, estimates are also given for what water requirements would be for wet- cooling technology.

Low Growth Scenario

One consideration that could potentially limit the number of new power faculties that can be built in the planning area is air quality. The Air Quality Division of the Wyoming Department of Environmental Quality (WDEQ) is responsible for insuring that new industrial facilities do not violate ambient air quality standards and that there is no significant deterioration to Class I air quality regions in eastern Wyoming and western South Dakota. As of August 2001, the WDEQ had approved an air quality permit for NAPG to build the Two Elk #1 Plant, and had received but not processed applications for NAPG's Two Elk #2 and Middle Bear Plants, as well as PHP&L's WyGen #2 facility. Those applications were on hold until the WDEQ could complete an updated baseline inventory of air parameters and meteorological conditions in the region. It would then be up to the applicants to demonstrate that their proposed facilities would not violate air quality standards given the updated baseline inventory. There is uncertainty at this time concerning the number of new plants that can be accommodated in the Basin due to air quality constraints (Olson, 2001). New power plant construction also faces uncertainty due to project financing considerations and leases and permitting for transmission facilities (Casper Star-Tribune, 2001). These factors, along with air quality considerations, could result in less additional capacity being built than is planned at this time.

The low growth scenario for future electric power production in the Basin assumes that only 50 percent of the 2390MW of new capacity discussed above will eventually be built. That additional capacity would bring total generating capacity in the Basin to 1625MW in the year 2030. Assuming dry cooling technology, total annual water use for power generation would rise to about 3,700 acre-feet annually by 2030. Almost all of this water would be supplied by groundwater wells. If low cost surface water or CBM water were available in sufficient quantities to make wet cooling technology practical for the new plants, water consumption would rise to about 20,800 acre-annually by the year 2030.

Moderate Growth Scenario

The moderate growth scenario for electric power production assumes that the permitting and financial uncertainties surrounding future expansion will be resolved over the next 30 years and that all currently planned capacity additions will be on line by that date. In that case, 2,390MW of additional generating capacity would be in place by the year 2030, bringing to the total to 2,820MW. Assuming dry cooling technology, total water requirements would be about 6,900 acre-feet annually.3 Assuming wet cooling technology for new generating units, total water requirements would rise to about 41,100 acre-feet annually.4

High Growth Scenario

The high growth scenario for electric power production assumes that all capacity additions envisioned for the moderate growth scenario will take place, and that an additional 1,200MW of capacity not yet announced will be added to help meet the nations growing energy needs. This additional capacity may require the adoption of new emissions control technology to meet air quality standards or the relaxation of those standards to allow increased production, neither of which is assured. Nevertheless, the assumption of 1,200 additional MW above the 2,390MW envisioned for the moderate growth scenario constitutes a reasonable high growth scenario forecast.

Total generating capacity for the high growth scenario is 4,020MW and total water requirements would be about 10,100 acre-feet annually.3 Assuming wet cooling technology for the new capacity would bring total water requirements to slightly over 70,000 acre-feet annually.4 Future electric power generation water use projections for all three growth scenarios are presented graphically in Figure 1.

Figure 1

Electric Power Water Demand Projections

Northeast Wyoming River Basins

2030

COAL MINING

The planning area is a major coal-producing region with enormous resources of low sulfur, low BTU coal that can be mined from the surface due to relatively shallow overburden. During the year 2000, there were 14 active mines in the Basin with a total annual production of 322.7 million tons (Burlington Northern, no date). This figure constitutes 95 percent of the total Wyoming coal production of 338.4 million tons in that year (Wyoming Coal Information Committee, 2001).

The coal mines in the planning area use water primarily for dust abatement and reclamation, with lesser amounts used for equipment wash-down and domestic purposes. The primary sources of water for most mines are dewatering wells drilled into the coal seam ahead of advancing pit operations and sump wells to remove water from the pit. A few mines are extracting dry coal, however, and have drilled groundwater wells away from the coal seam to meet their needs. Surface runoff is also captured in some operations. Water use varies considerably among mines and by season of the year, with summer being the peak usage season. The mine personnel interviewed for this study reported usage rates of between 182 and 803 acre- feet of water annually. Some mines discharge a far greater amount of water than they use because their dewatering activities produce more water than they need for operational purposes.

Future water use by the coal industry in the planning area is expected to increase slightly for two reasons. First, the pits at some mines are expanding away from the coal processing facilities on site, thus requiring longer hauls and more water use for dust suppression. Second, some mines anticipate expanding production in the future if coal prices remain firm at current levels or increase. Nevertheless, most mines will continue to meet their operational water needs from dewatering wells and sumps on site. These activities are not expected to affect either surface water resources or other groundwater users in the Basin. Thus, water requirements for the mining industry have not been projected into the future.

OIL AND NATURAL GAS PRODUCTION

Traditional oil and gas production in the planning area has been declining in recent years. According to the Bureau of Land Management (2001), the number of wells plugged is expected to exceed the number of wells drilled each year for the foreseeable future. This trend will be offset by an increase in coalbed methane (CBM) production as discussed in the following section.

Very little water is consumptively used by the oil and gas industry in the planning area; only small amounts are consumed for domestic purposes and to create drilling mud. Pumping operations generally produce water as a by-product of oil and gas production. This process water can be re-injected or discharged (with appropriate permits) depending upon circumstances. Water flooding operations are sometimes carried out on mature fields to provide flooding water. There are about 240 such wells in the Powder/Tongue and Northeast Wyoming River Basins combined (HKM, 2002).

Future water use by the oil and gas industry may increase if energy prices remain strong and provide an incentive for enhanced recovery in mature fields. The extent of the increase will depend upon the recovery technology adopted by producers for various fields. One process, called Alkaline Sulfacant Polymer (ASP) Enhancement, requires clean soft water for recovery process. If adopted widely, it could result in a need for new wells to produce clean water since by-product water is usually dirty (Kane, 2001). Alternatively, CBM byproduct water could be used in this process if it is available in the right quantity and quality.

Another enhanced recovery process uses CO2 to flood oil fields. Widespread adoption of this technology depends upon the construction of a CO2 pipeline into the Basin to reduce costs. If such a pipeline is built, CO2 recovery is expected to become the dominant enhanced recovery method (Kane, 2001). In that case, water use by the oil and gas industry would decrease. In any case, water use by the oil and gas industry is generally non-consumptive, is spread over a large geographic area, and does not impact either surface water resources or other groundwater users in the Basin. For these reasons, future requirements for this industry have not been quantified.

COALBED METHANE PRODUCTION

Coalbed methane (CBM) production has become widespread in planning area over the past few years. CBM development is not a consumptive user of water resources, but produces groundwater as a by- product of gas production. The process involves pumping water from coal seams to relieve pressure on methane gas so that it can be captured at the surface. The availability and disposal of CBM process water presents both problems and opportunities in the formulation of a water plan for the Basin.

Information obtained from the Wyoming Oil and Gas Conservation Commission indicates that as of April 2001, there were 3,647 CBM wells in the planning area, with a total water discharge of approximately 33,000 acre-feet annually (HKM, 2002). The vast majority of these wells (89 percent) are located in the Upper Belle Fourche sub-basin due to the proliferation of coal seams in that area. Smaller numbers of wells are located in the Upper Cheyenne and Antelope Creek sub-basins.

Projections of future CBM activity and water production in the planning area are being prepared by the BLM for use in a forthcoming EIS, scheduled for release in late 2001 or early 2002 (Beels, 2001). The BLM has made a draft version of their projections available to the project team and the results are incorporated into this memorandum. These projections are presented with the caveat that they are preliminary and subject to revision prior to release of the draft EIS. If available, updated projections will be included in the final version of this memorandum.

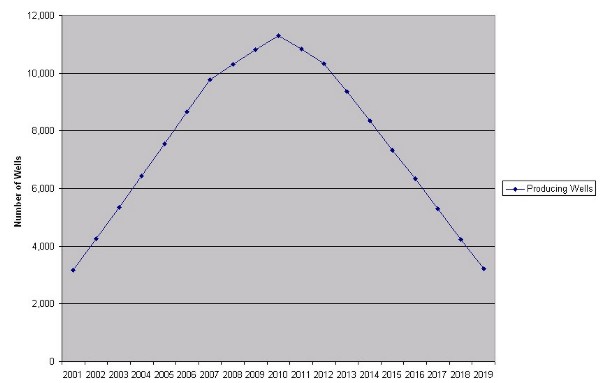

The BLM's projected number of CBM production wells for the planning area is given in Figure 2. That figure shows that the number of production wells is expected to rise from about 3,200 in 2001 to a peak of almost 11,400 wells in the year 2010. Thereafter, the number of wells is expected to decline gradually to a total of about 3,000 by the year 2019.

Figure 2

Projected Number of CBM Production Wells

Northeast Wyoming River Basins

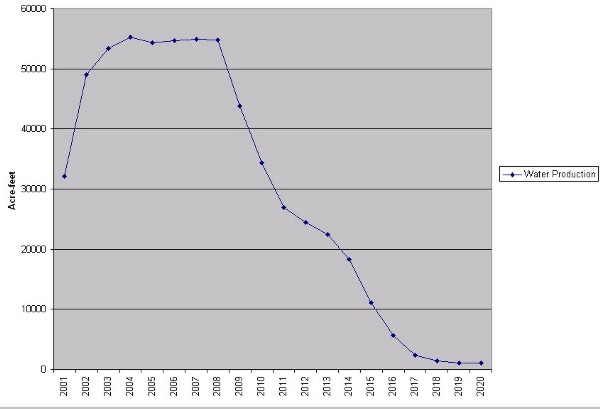

Projected water production for Northeastern Wyoming CBM wells is depicted in Figure 3 for the period from 2001 through 2020. That figure shows that produced water is expected to grow in volume from about 32,000 acre-feet in 2001 to a peak of around 55,000 acre-feet annually by the year 2005. Production is expected to remain at that level for about five years, and then drop off dramatically to only a few thousand acre-feet annually after the year 2016. The relatively short-lived production of significant amounts of CBM water makes it unlikely that it will prove useful for ongoing industrial purposes such as electric power generation. Utilities that make heavy investments in generating plants would require a more secure long-term source of operational water as such plants are typically designed for a 50-year operational life.

Figure 3

Projected Annual CBM Water Production

Northeast Wyoming River Basins

The projected rapid drop off in CBM production water over the planning horizon reflects the fact that wells typically produce large amounts of water initially to free gases from the coal seam, but that water production drops off as gas production increases. The BLM's assumptions concerning water production for a typical CBM well are that it will produce 500 barrels of water per day during the first year of operation, but that production will drop off rapidly to only nine barrels per day by year six. The BLM assumed an average 11-year production life for CBM wells, with no water production at all after year eight.

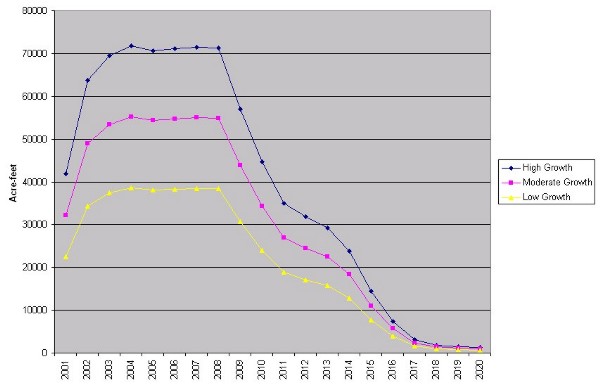

Figure 4 presents low, moderate, and high growth scenario projections for CBM water production in the planning area. These projections were generated by assuming that the level of uncertainty associated with the BLM projections can be captured by a range of plus or minus 30 percent. The results show that peak water production could fall in a range from about 38,000 to 72,000 acre-feet annually, but is nevertheless expected to drop off dramatically during the period from 2010 to 2020.

Figure 4

CBM Water Production Scenarios

Northeast Wyoming River Basins

COAL CONVERSION FACILITIES

Several companies have studied the possibility of building coal conversion facilities in the planning area over the past 20 years. There appear to be two rationales for such facilities. One rationale is the fact that coal contains a high percentage of water by weight, meaning that eliminating or reducing the water content of coal prior to shipment could mean substantial savings in transportation costs to out-of-state utilities and other users. The second rationale is that the vast coal reserves of the region could be used to produce synthetic versions of fuels such as gasoline if petroleum prices were to increase or government programs were in place to stimulate domestic energy production.

Since 1980, three such facilities have been issued construction permits by the Wyoming Industrial Siting Administration, although none have been built to date. The first facility to receive a siting permit was a coal-to-gasoline plant proposed by Hampshire Energy in the early 1980s. The facility would have utilized six million tons of coal annually to produce 1.5 million barrels of unleaded gasoline. It would have utilized approximately 5,000 acre-feet of water annually, from groundwater sources. According to the company's industrial siting application, a pipeline from Lake DeSmet was considered a source of plant water, but that the groundwater option was deemed preferable from both environmental and financial perspectives (Hampshire Energy, 1981). Project construction was deferred indefinitely when the U.S. Department of Energy abandoned a subsidy program designed to stimulate domestic energy production.

In the 1990s two companies received Industrial Siting Permits to build facilities that would convert coal to liquid and dry fuels with lower water content. One such facility would convert 12 million tons of coal annually to six million tons of briquettes for use as boiler fuel for power generation or other purposes. It would use about 1,000 acre-feet of groundwater annually (Fassett, 1997). Another facility would convert six million tons of coal annually to 1.5 million tons of coal-derived liquid (CDL) that could also be used as an industrial fuel. This facility would utilize about 1,200 acre-feet of groundwater annually (Planning Information Corporation, 1994). Neither of these facilities has been constructed to date, possibly due to declining coal prices during much of the past decade.

Projections of future water requirements for coal conversion facilities are presented in Figure 5. For the low growth scenario no water requirements are shown. It was assumed that the market forces that have prevented the construction of such facilities in the past would continue throughout the 30-year planning horizon. For the moderate growth scenario, however, it seems reasonable to assume that some facilities that convert coal to more concentrated fuels will be built. In this case, it was assumed that two such facilities would become operational, one to convert coal to solid fuels and one to convert coal to liquid fuels. Based upon the water requirements of the two such plants described above, total water requirements for this scenario are 2,200 acre-feet annually. Barring an inexpensive source of surface water, this demand would probably be met from groundwater sources.

Figure 5

Coal Conversion Water Demand Projections

Northeast Wyoming River Basins

2030

The high growth scenario assumes that the United States places an increasing emphasis on energy self- sufficiency over the next 30 years, including the adoption of industry incentives to find alternatives to imported oil. Under this scenario, it is reasonable to assume that addition to the coal conversion facilities described above, at least one coal-to-gasoline plant will become operational in the planning area over the next 30 years. This plant would have an annual consumptive water use requirement of approximately 5,000 acre-feet annually, bringing total water use for the high growth scenario to 7,200 acre-feet annually. Again, this requirement would most likely be met from groundwater sources.

OTHER POTENTIAL FUTURE USES

The industrial water use projections described above focus on existing industrial uses or those that have been proposed but not implemented in the past. The potential for other water-intensive industries, not discussed above, to relocate to the planning area over the next 30 years also warrants discussion.

According to the U.S. Department of Commerce (1996), four industry groups in the United States account for over 95 percent of all industrial water use. Those industries are (1) electric power producers, (2) chemical and allied products manufacturers, (3) primary metals producers, and (4) paper and allied products manufacturers. Electric power producers alone account for over 80 percent of all industrial water use in this country each year. The other three industrial groups account for roughly 14 percent of all industrial water use.

Electric power generators are already represented in the Basin, and projections of their future water requirements are discussed above. The other three water-intensive industries, chemicals, primary metals, and paper, tend to locate in areas close to their primary inputs. The fact that none have located in the planning area in the past is an indication that commercially viable resources needed for their manufacturing operations are not present on a competitive basis compared to other regions of the country. Although this situation could change in the future as resources are exhausted elsewhere, such developments are not foreseeable at this time and therefore not discussed further in this memorandum.

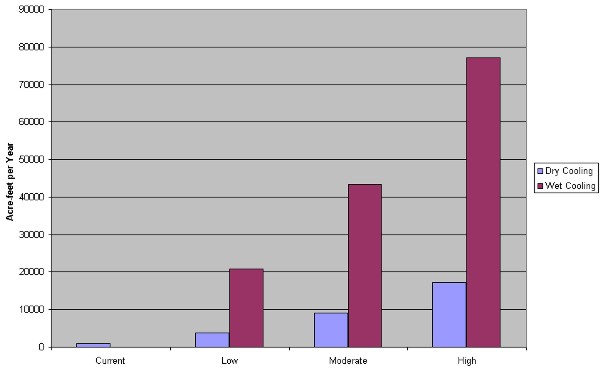

SUMMARY OF FINDINGS

The largest demand for industrial water in the planning area over the next 30 years is expected to be associated with the construction of new coal-fired electric generating facilities. A smaller amount of water will be needed for facilities that convert coal to alternative fuels. Barring the development of an inexpensive source of surface water, it is expected that these industrial needs will be met through the adoption of water conserving technologies such as dry cooling for power generation and the development of groundwater resources to meet projected needs. If an inexpensive source of surface water were available, industry could employ more efficient wet cooling technologies for power generation and would have correspondingly larger water requirements.

These findings are depicted in Figure 6, which summarizes total industrial water requirements for the two different assumptions concerning power generation cooling technology. For the dry cooling option, total industrial water requirements are expected to rise from a current level of 900 acre-feet annually to between 3,700 (low scenario) and 17,300 (high scenario) acre-feet annually by the year 2030. The moderate growth scenario estimate is 9,100 acre-feet annually.

For the wet cooling option, total water requirements would grow to between 20,800 (low scenario) and 77,200 (high scenario) acre-feet annually by the year 2030. The moderate growth scenario estimate is 43,300 acre-feet annually. Although coalbed methane production water could provide enough water to meet the requirements of the wet cooling option on a short-term basis, it is not projected to be available over a long enough time period to warrant investments in wet cooling technology for power generation.

Figure 6

Total Industrial Water Demand Projections

Northeast Wyoming River Basins

2030

REFERENCES

Beels, Paul. 2001. Electronic spreadsheet model of projected CBM wells and water production. Bureau of Land Management. Buffalo Field Office. June 1.

Bureau of Land Management. 2001. Reasonably Foreseeable Development Scenario for Oil and Gas Development in the Buffalo Field Office Area, Wyoming. Buffalo Field office. U.S. Department of the Interior.

Burlington Northern and Santa Fe Railway. No Date. Guide to Coal Mines Served by Burlington Northern and Santa Fe Railway. Ft. Worth, Texas.

Casper Star-Tribune. 2001. Transmission Contracts Expire. Article by Dustin Bleizeffer. August 23.

Fassett, Gordon W. 1997. State Engineer's Preliminary Opinion of the Water Supply and Water Yield Analysis for the Encoal LFC Plant Water Supply. October 27.

Hampshire Energy. 1981. Industrial Siting Application: Coal to Gasoline. Submitted to the Wyoming Industrial Siting Administration. September.

Henshaw, Bernadette. 2001. Personal Communication. Pacific Power Company. May 30.

HKM Engineering. 2002. Northeast Wyoming River Basins Plan: Industrial Water Uses. Technical Memorandum prepared for the Wyoming Water Development Commission. June.

Kane, Kevin. 2001. Personal communication. Environmental Manager, Citation Oil Company.

Mueller, Steven. 2001. Personal communication. Black Hills Power Company. May 21.

Olson, Dan. 2001. Personal communication. Director, Air Quality Division, Wyoming Department of Environmental Quality. August 23.

Parish, Denise K. 2000. Personal communication. Wyoming Public Service Commission. May 24.

Planning Information Corporation. 1994. Puron PRB Project Request for Waiver of Permit Application. Submitted to the Wyoming Industrial Siting Division, Department of Environmental Quality. December 13.

Roeper, Dennis. 2001. Personal communication. Osage Station Plant Manager. Black Hills Power and Light. May 31.

Ruffato, Mike. 2001. Personal communication. North American Power Group. May 25.

U.S. Department of Commerce. 1996. 1992 Census of Manufacturers: Water Use in Manufacturing. Bureau of the Census. March.

Watts, Gary. 2000. Green River Basin Plan Industrial Water Needs Projections. Technical Memorandum prepared for the Wyoming Water Development Commission. December 11.

Wyoming Coal Information Committee. 2001. Wyoming Coal 2001. Wyoming Mining Association. Cheyenne.

Wyoming State Engineer. 2001. Electronic files listing industrial water rights permit holders in northeastern Wyoming.

2The 2,820MW figure does not include the 33MW Osage plant that is not expected to operate beyond the year 2010.

3This estimate is based upon existing water use and water use estimates for new facilities supplied by NAPG for the Two Elk Power Plant, which will consume an estimated 800 acre-feet of groundwater annually to generate 300MW of power (Ruffato, 2001).

4 This estimate is based upon existing uses and the wet cooling water requirements for the Jim Bridger Power Plant in Sweetwater County, Wyoming (Watts, 2000).